DOUBLE WIDE DRIVE-IN PALLET RACKING

TWINLODE RACKS

TWINLODE RACKS

Double wide drive-in pallet racking systems, otherwise known as Twinlode racks, are high-density storage solutions that optimize space by making maximum use of the floor area and height of your warehouse.

Twinlode racks utilize deep lane storage to reduce space usage, cut operational costs, and maximize storage density. This type of pallet racking system is commonly used in high-volume applications for storing a limited number of SKUs.

If you are looking for a reputable and trusted partner for double wide drive-in pallet racking systems, you have come to the right place. Twinlode Automation has decades of industry experience installing high-density storage solutions for companies around the world.

The term “Twinlode” originated over 20 years ago when we invented a storage solution for a world-leading company in the beverage industry. This single word is unanimously known in material handling for Double-Wide Drive-In racking.

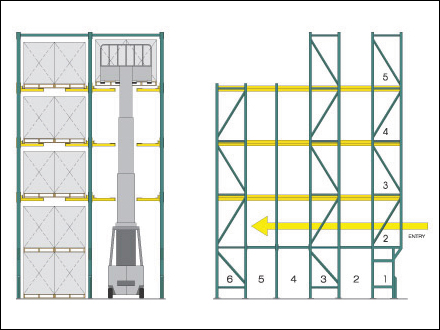

Twinlode Automation is the inventor of the “Twinlode” double wide drive-in rack. Our dual-wide storage systems allow two pallets to be loaded and unloaded at once, which increases productivity and decreases wear and tear. Dual-wide Drive In racking also has fewer uprights in the pallet position, which improves space utilization and storage density.

Material Handling is in our DNA

Our dual-wide storage solutions are high-density rack systems that use 35% less overall square footage. Deep lane storage holds more loads, cuts costs, and reduces space usage. Additionally, these racking systems enable the loading and unloading of two pallets at a time, saving money and time.

Twinlode Rack is the preferred storage solution for high-volume warehouse operations that handle two pallets at a time. Applications for Twinlode, high-density storage racking include:

These environments have limited storage space and high activity, requiring a need for efficient and durable material handling systems. Dual-wide storage systems improve storage densities in these industries while improving product access.

Twinlode Racking is available in our standard structural c-channel. It can be custom designed for any application, to accommodate any size pallet or load. Twinlode finishes include our standard electrostatic paint in your choice of many colors, powder coat or hot-dipped galvanized.

Regarding racking construction, double wide systems most commonly utilize structural steel over roll-form because of its structural capabilities and strength.

Some of the many advantages structural steel offers are higher weight capacities, higher resistance to forklift damages, and increased safety because of its durability and strength.

The advantages of Drive In and Drive Thru racking include:

Twinlode lowers your labor and equipment costs, reduces the need for additional square footage, and eliminates shuttle costs. The Twinlode rack system pays for itself and more! It’s a much more viable alternative to building or leasing additional space.

The Twinlode drive-in rack system, designed around the double-wide concept, allows two-at-a-time, side-by-side pallet transport and storage. Using double or single/double forklift attachments from trailer to rack, Twinlode can increase your productivity by over 50%.

Because Twinlode allows you to store pallets side-by side, an additional upright in every pallet position is eliminated. This gives you more pallet storage. Wider bay widths also keep the forklifts farther away from the uprights, eliminating damage to your rack system.

With hundreds of thousands of pallet positions in service worldwide, Twinlode is a trusted choice for customers globally.

Double wide drive-in pallet racking is susceptible to damage, due to the design and presence of moving forklifts. It is essential to plan for regular rack inspections and repairs of your drive-in racking system to identify damage, since its structural integrity can be compromised by forklift accidents. Protect your storage system and prevent workplace accidents by signing up for a one-time audit or annual maintenance plan.

Twinlode Automation has more than 40 years of experience providing storage solutions for warehouse management. We provide the material handling industry Drive In as well as traditional pallet rack systems and automated solutions. We also offer support through our professional services for consultation, design, and implementation.

Learn more about our Twinlode racks by contacting us online today.

Our pallet rack engineers and warehouse design consultants will help you select the right solution for your operational needs.