DRIVE-IN & DRIVE-THRU PALLET RACKING

HIGH DENSITY STORAGE

HIGH DENSITY STORAGE

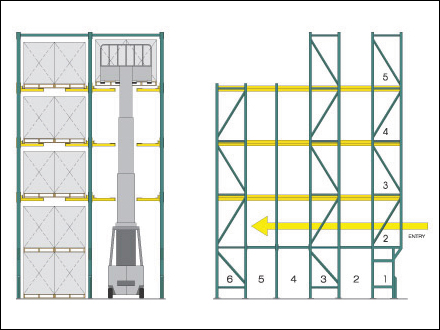

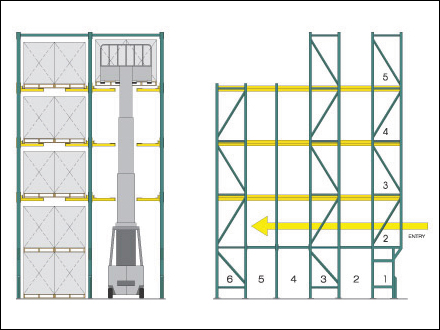

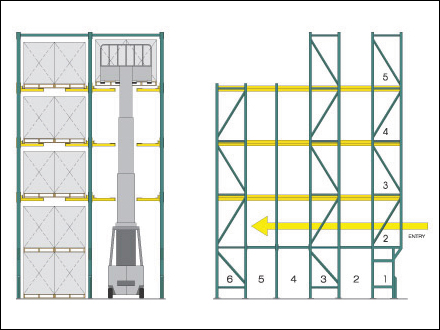

Drive In and Drive Thru pallet racking systems are high-density storage solutions that optimize space by making maximum use of the floor area and height of your warehouse. Drive-In and Drive-Thru racking utilize deep lane storage to reduce space usage, cut operational costs, and maximize storage density. This type of pallet racking system is commonly used in applications for storing a limited number of SKUs. While selectivity is not prioritized for Drive-In and Drive-Thru pallet racking systems, it reduces overall square footage requirements when compared to other types of storage solutions.

If you are looking for a reputable and trusted partner for Drive In or Drive Thru pallet racking systems, you have come to the right place. Twinlode Automation has decades of industry experience installing high-density storage solutions for companies around the world. The term “Twinlode” originated over 20 years ago when we invented a storage solution for a world-leading company in the beverage industry. This single word is unanimously known in material handling for Double-Wide Drive-In racking.

Our Drive In/Drive Thru pallet racking is available in single-wide and double-wide options. Single-wide racking is one pallet wide. Our dual-wide storage systems allow two pallets to be loaded and unloaded at once, which increases productivity and decreases wear and tear. Dual-wide Drive In racking also has fewer uprights in the pallet position, which improves space utilization and storage density.

Material Handling is in our DNA

Drive In and Drive Thru storage solutions are high-density rack systems that use 35% less overall square footage. Deep lane storage holds more loads, cuts costs, and reduces space usage. Though they are both dependable racking options, these Twinlode rack systems have some key differences.

Drive In systems are one-sided racking solutions ideal for Last-In First-Out (LIFO) inventory management and facilities with limited space. With a Drive In system, drivers can load and retrieve pallets from the same entry point at which they were loaded, achieving LIFO inventory management. Drive In racks feature an anchor bay for added stability at the rear of the structure, which limits forklift access. This support at the back end allows the front to be open for access without compromising the structure’s stability.

Drive Thru racking is a two-sided racking solution that supports First-In First-Out (FIFO) inventory management. With a Drive Thru pallet racking system, pallets are loaded into one side of the racking system and unloaded on the opposing side, ensuring that the oldest goods are picked first. The two points of access allow for more flexibility in loading and unloading pallets from the rack system. The internal anchor bays provide the beams and bracing the structure needs for support, which allows two-sided access. Since both sides of the rack need to be accessible, Drive Thru systems are best in facilities that have the space for two aisles.

Since Drive In racking has one entrance, the forklift operator uses this opening to load palletized goods onto the guide rails at the back of the system. Since the pallets sit on guide rails, they are not bulk stacked. Newer products are loaded in front of older products by being loaded from the ground level to the highest level and from front to back. When unloading, the process is inversed as the operator takes the load closest to the front or from the top, which is the most recently stocked. It is essential to clear all SKUs from each lane before adding new products.

These systems allow forklift operators to traverse the entire length of the system, so the need for space-demanding aisles for truck movement is greatly decreased. It enables better use of available space through denser storage. Products can be packed tighter since these racks can be placed against the wall or in the corner. This racking system is ideal for products that have a rapid turnover and do not need to be rotated.

Drive Thru racking systems have two entrances, so forklifts can pass through the rack structure entirely. The forklift operator can use one opening to load goods onto the rails and the side closest to the shipping dock doors for unloading. When unloading, the operator retrieves from the opposite of the loading side to ensure FIFO inventory management.

Since two aisles are required for access, these systems are ideal for warehouses with larger areas of storage space. The ability to drive through the racking allows pallets to be stored deeper in the structure, which saves space. This racking system is best for products that need regular rotation.

Regarding racking construction, both systems most commonly utilize structural steel over roll-form because of its structural capabilities and strength. Some of the many advantages structural steel offers are higher weight capacities, higher resistance to forklift damages, and increased safety because of its durability and strength.

The advantages of Drive In and Drive Thru racking include:

Drive In and Drive Thru racking systems cost less than some other racking systems and support high-density storage, which many warehouses need.

The flexibility of dual-wide storage systems allows more product to be loaded or unloaded at once with a double or single/double forklift.

The elimination of additional uprights for every pallet position allows more products to be stored in the same space.

Facilities that need to use their storage space efficiently benefit from Drive In and Drive Thru racks. These racking systems offer greater storage density than other systems, resulting in high space savings.

Potential applications for high-density storage racking include:

These environments have limited storage space and high activity, requiring a need for efficient and durable material handling systems. Dual-wide storage systems improve storage densities in these industries while improving product access.

Drive-in pallet racking is susceptible to damage, due to the design and presence of moving forklifts. It is essential to plan for regular rack inspections and repairs of your drive in racking system to identify damage, since ts structural integrity can be compromised by forklift accidents. Protect your storage system and prevent workplace accidents by signing up for a one-time audit or annual maintenance plan.

Twinlode Automation has more than 40 years of experience providing storage solutions for warehouse management. We provide the material handling industry Drive In and Drive Thru racks as well as traditional pallet rack systems and automated solutions. We also offer support through our professional services for consultation, design, and implementation.

Learn more about our Drive In/Drive Thru racking by contacting us online today.

Our pallet rack engineers and warehouse design consultants will help you select the right solution for your operational needs.