Vertical Lift Modules

VLM

VLM

A Vertical Lift Module, also known as VLM, is a type of automated storage and retrieval system with a modular design to improve storage density, pick accuracy, and space utilization. Because of its ability to store hundreds to thousands of SKUs, VLMs are quickly becoming the standard storage solution to maximize vertical space for operations looking to consolidate storage of boxes, trays, totes, spare parts, and smaller products.

Unlock the power of vertical space in your facility with cutting-edge Vertical Lift Modules (VLMs) to revolutionize storage capability, efficiency and organization.

Unlock the potential of vertical space and optimize your storage capabilities like never before. Whether you need a single VLM for basic storage or multiple VLMs for order fulfillment, consolidation, or buffering, our vertical lift module solutions maximize your available floor space. Experience increased productivity and enjoy a rapid return on investment (ROI) for your operations.

Vertical Lift Modules (VLMs) offer unparalleled advantages when it comes to warehouse automation investment. The remarkable flexibility of VLMs ensures that your investment can cater to both current and future requirements. By integrating VLMs into your order fulfillment operation, you can benefit from:

Vertical Lift Modules (VLMs) offer a multitude of advantages, including space optimization, labor efficiency, and improved productivity, benefiting organizations across various applications within warehousing, distribution, and manufacturing. Some notable examples include:

Explore the limitless possibilities of Vertical Lift Modules (VLMs) by leveraging a range of options and accessories that enhance their functionality. VLMs can seamlessly integrate with pick-to-light systems, enabling increased pick accuracy and efficiency. Additionally, when combined with autonomous mobile robots (AMRs), VLMs facilitate effortless transportation of items or trays to subsequent workstations or designated areas, optimizing workflow and productivity. Discover how these versatile options and accessories can take your storage and retrieval operations to the next level.

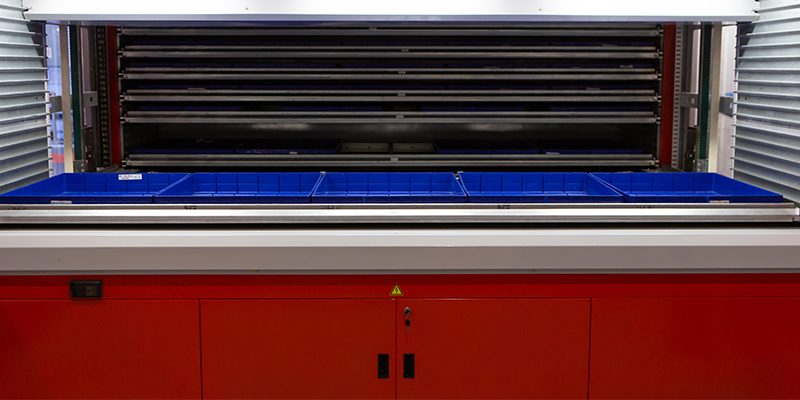

A VLM is a tall storage system consisting of multiple trays or shelves stacked vertically. To access items stored in the VLM, a user typically interacts with a control panel or software interface.

When a retrieval request is made, the VLM’s automated mechanism, often called an elevator or extractor, is activated. The elevator moves vertically within the VLM, locating the tray that contains the requested item. The trays are designed to store items in an organized manner, with each tray capable of holding multiple products.

Once the tray is positioned at the access point, the VLM opens the tray, presenting the item to the user at a convenient height for retrieval. The user can then remove the item from the tray.

After the retrieval is complete, the VLM’s elevator returns to its home position, ready for the next retrieval request. The system keeps track of inventory levels, automatically updating as items are retrieved or stored, ensuring accurate inventory management.

Overall, a VLM streamlines the storage and retrieval process by utilizing vertical space and automated vertical movement. This efficient system reduces the need for manual searching, minimizes physical effort, and improves accuracy in locating and retrieving items from the VLM.

Twinlode Automation provides over 40 years of material handling and storage system experience. By understanding the business requirements and examining the data, we bring a systematic approach to each business case with a solutions-focused mindset irrespective of the technology or process. This ability to deliver customized solutions distinguishes Twinlode from a typical materials handling dealer.

Vertical Lift Modules by Twinlode Automation are designed to increase your storage capacity within a smaller footprint. We have more than 40 years of experience designing and implementing storage systems for global brands. We also offer professional services for design, consultation, and implementation.