23 Jan How to Select a Warehouse Racking System

Distribution centers and warehouses rely on well-designed material handling and storage systems to support accurate inventory management to meet customer and partner needs. Using the right equipment for the application is key to ensuring warehouse efficiency, and since no two operations are alike, generally a cookie-cutter approach will not work. With the right pallet rack system, warehouses can optimize their operations and save valuable time and money in the process.

Several types of pallet racking systems are available, each with unique characteristics that make it suitable for various applications. Discover how to choose a pallet racking system, factors to consider in the decision-making process, and the types of racking systems a warehouse might implement.

What Is a Warehouse Racking System?

A warehouse racking system, also called a pallet racking system, is a part of warehouse infrastructure that stores inventory for optimal material flow and operational efficiency. Pallet racking systems are constructed using metal upright frames and horizontal beams to securely hold pallets, cases, kegs, and oddly shaped merchandise. Warehouse rack solutions can be anywhere from 15-60 feet tall and often require a forklift to retrieve the materials.

Racking systems provide several benefits, including:

- Increased storage density: High-density storage racking can help warehouses and distribution centers store and organize large quantities of materials and inventory, allowing for greater pallet storage within the same footprint.

- Inventory management: A well-organized inventory storage system is a valuable tool for increasing a warehouse’s operational efficiency. Racking systems enable warehouses to track inventory better at each stage of the inventory cycle, from storage to retrieval for order fulfillment.

- Improved space utilization: Since floor space is limited and every square foot is highly valuable in a distribution center, a well-designed pallet rack system enables a business to make the most efficient use of a facility floor plan by increasing the storage capacity into a smaller footprint, expanding the useable space for other operational needs.

Factors to Consider When Selecting a Warehouse Racking System

Every application is unique, requiring different racking systems to ensure the storage system meets operational goals. Here are some of the top factors to consider when choosing a pallet racking system:

1. Product and Material Flow

Product flow is the way inventory moves throughout the warehouse. Each stage of product flow requires space-saving solutions, from receiving and storage to picking and shipping. How a warehouse optimizes its product flow depends on its inventory management method and facility layout.

Two popular methods are first-in, first-out (FIFO) and last-in, first-out (LIFO). Specific pallet rack systems are better suited for FIFO inventory scenarios, while others are better suited to the LIFO method. Understanding how product flow impacts inventory and materials storage helps businesses select the ideal pallet rack system for their operation.

2. Warehouse Layout

The layout of a warehouse facility also determines the ideal pallet racking system for an operation. Distribution centers have limited floor space, so their racking systems should optimize it. The vertical space available in a warehouse is an important component, as it impacts the height of the warehouse storage system.

A pallet rack provider offers the experience and personalized attention to help businesses select the racking system with the right layout for its specific application and operational requirements.

3. Pallet Characteristics (Weight & Dimensions)

The size, shape, quantity, and weight of the inventory needing storage affect the type of material handling and storage solution a warehouse may use. The space on the rack must align with the space needed for inventory to store palletized loads efficiently.

Rack depth significantly impacts a pallet rack system’s storage density. Double deep pallet rack systems allow warehouse employees to store two pallets deep, while a single deep rack system only enables storage of one pallet deep.

4. Budget

A warehouse or distribution center’s budget is essential in deciding what type of pallet racking system to use. While having a budget is vital for helping a warehouse meet its financial goals, low-priced options may not always be the best.

Structural steel racking may cost more than other racking systems upfront, but the return on investment can be sizeable. Structural racking provides superior durability and strength, lasting far longer than alternatives such as roll-formed racks.

5. Safety

Employee safety is a priority for warehouses. Storage systems that are structurally sound, durable, and designed for the warehouse’s specific location and application provide optimal safety for its operations and staff.

Pallet rack suppliers construct their systems out of steel to ensure they can support a wide range of materials and load requirements. Ensure the racking design include clearances for truss and fire sprinklers, among other local and state codes.

6. Accessibility

Warehouse employees and operators must be able to access pallets and materials stored on racking systems quickly and efficiently. Two important considerations for accessibility are which type of forklifts are used and how wide the aisles must be.

When selecting a warehouse racking system, keep in mind the limitations of existing material handling equipment. Certain types of equipment are better able to handle inventory of different heights and weights. For example, a double deep selective rack system requires a deep reach truck.

7. Versatility

Many warehouses use multiple types of racking systems in their operations due to the need to accommodate products of various weights and sizes. Utilizing a versatile pallet racking system allows warehouses to use one solution for multiple products and applications. For example, warehouses may use selective, Drive In, push back or other types of racking to optimize their efficiency and enable more variety in their inventory and material handling.

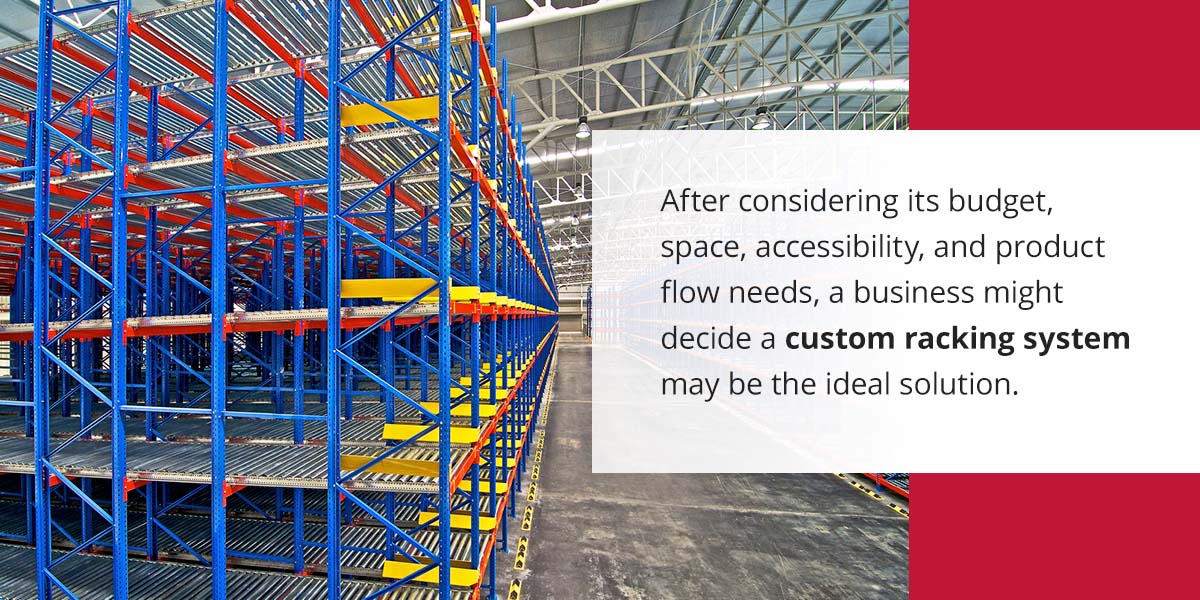

8. Custom Solutions

8. Custom Solutions

After considering its budget, space, accessibility, and product flow needs, a business might decide that custom racking systems are the ideal solution. A vendor that designs custom storage racks to fit a physical layout, provides necessary storage for expansion, and optimizes accessibility helps streamline inventory management.

Different Racking Types

Warehouses and distribution centers use many pallet racking systems to streamline operations. Here are some of the most popular pallet rack systems on the market:

Selective

A selective pallet racking system, also known as a standard rack, provides direct access to each pallet in storage, allowing forklift operators to pick any pallet without needing to move any others. Because selective racks allow the first pallets stored to be the last ones picked, this racking system is ideal for FIFO inventory management. Selective pallet racks are available in single deep or double deep configurations to increase storage density.

Pallet Flow

For high-volume warehouse operations, pallet flow racking could be the ideal solution. Pallet flow racks use gravity to index pallets forward along a sloped lane using rollers, flow rails or wheels. These racking systems enable the FIFO inventory management method because forklift operators place pallets into the charge end, which moves pallets for efficient and accessible picking on the discharge end.

Push Back

The push back pallet racking system enables high-density storage for two to six pallets deep. These pallet racking systems work by placing pallets on nesting carts that new pallets “push back” as the forklift loads them. Push back racking enables LIFO inventory management because the last pallet loaded into the lane is the first pallet a forklift operator unloads.

Drive In and Drive Thru

Whereas other pallet racking systems require forklift operators to access the pallets from the aisle, Drive In and Drive Thru warehouse rack systems reduce the need for excess aisles. Drive In racking systems are one-sided, enabling forklift operators to load and access pallets from a single entry point for LIFO stock rotation. Drive Thru systems direct forklift operators in one entry to load pallets and allow them to unload from the opposite side, satisfying FIFO operations.

Case and Carton Flow

A case and carton flow racking system, similar to pallet flow, incorporates wheeled tracks on a sloped lane to move cases and cartons along the rack. Warehouse employees load merchandise in the rear of the rack and allow it to roll forward using braking systems to control the speed. Case flow is often configured with Push Back on upper levels to streamline inventory replenishments in the FIFO case picking operation.

Keg Flow

A keg flow racking system is primarily used by beverage distributors and breweries to organize and store large quantities of beer kegs. Utilizing gravity and rollers to move kegs toward the unload (discharge) end. Forklift operators have access to kegs from either side of the racking system, so they can load and unload from the front or back.

Find the Right Pallet Rack System With Twinlode Automation

Find the Right Pallet Rack System With Twinlode Automation

Identifying the best pallet racking system allows warehouses to optimize their loading and unloading processes and improve efficiency on the warehouse floor. With several factors influencing a warehouse’s choice of racking system, the decision can seem overwhelming. Partner with an expert pallet racking systems provider that offers professional advice and customized pallet racking systems.

Twinlode Automation designs, integrates and implements best-in-class material handling solutions. Utilizing the latest in material handling engineering and supply chain technology, Twinlode Automation helps you choose an effective warehouse storage solution for your unique operation.

For help selecting the best type of pallet rack system, contact the team at Twinlode Automation.

8. Custom Solutions

8. Custom Solutions