Twinlode Automation is well-equipped with the personnel and experience required to design storage solutions for operations’ unique workflows and supply chain goals. Through evaluation of processing needs, inventory loads, methods, and goals, our warehouse engineering team will use their exhaustive understanding of each pallet and case storage system to develop an effective solution for your operation. These assessments also account for factors such as warehouse footprints, seismic zoning, and other facility conditions.

Whether an operation aims to improve storage capacity, increase throughput, or integrate automated material handling solutions, Twinlode Automation can develop the best possible solution.

Warehouse Engineering Capabilities

Twinlode Automation provides warehouse engineering and design services from beginning to end through site surveys, warehouse layout assessments, preliminary calculations, calculation package and stamped drawings, and as-built installation drawings. Our team of experienced engineers guides this process to deliver a high-value final product.

Through these five stages, we develop an understanding of a site and workflow to design systems that optimize space while integrating all required features. Our experience with pallet rack solutions enables us to deliver a design that addresses every requirement. The final installation drawing will exemplify outstanding functionality through seasonality changes, new material handling solutions, adjustments to inventory management, and many other factors.

Site Survey

This initial stage involves the collection of building information, measurements, and potential interferences in warehouse design. Site surveys also consider daily operations, staffing, and facility flow. Our engineers will apply these factors to develop a storage system that is compliant and works efficiently with existing workflows.

Warehouse Layout and Design

The design team will assess several factors to determine the right size for a facility’s system. These factors include:

- Historical and forecasted inventory

- Days-on-hand requirements

- Seasonality

- Accessibility

- Utilization

- SKU proliferation

- Inventory management (FIFO/LIFO)

Additionally, the Twinlode Automation team will design the system around any existing and future equipment, obstructions, columns, electrical panels, pedestrian walkways, and other long-term or permanent fixtures in the space. These designs also account for safety measures within the facility and involve collaboration with operations and vehicle suppliers to ensure the storage system is safe and accessible for the equipment fleet.

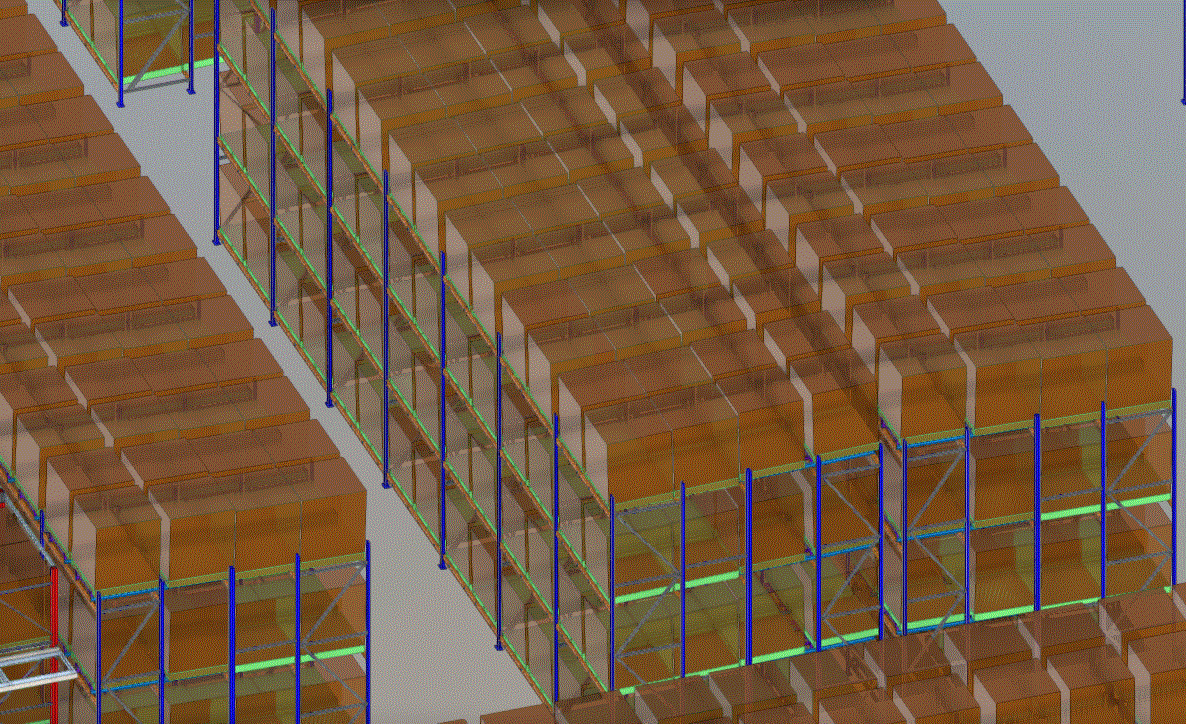

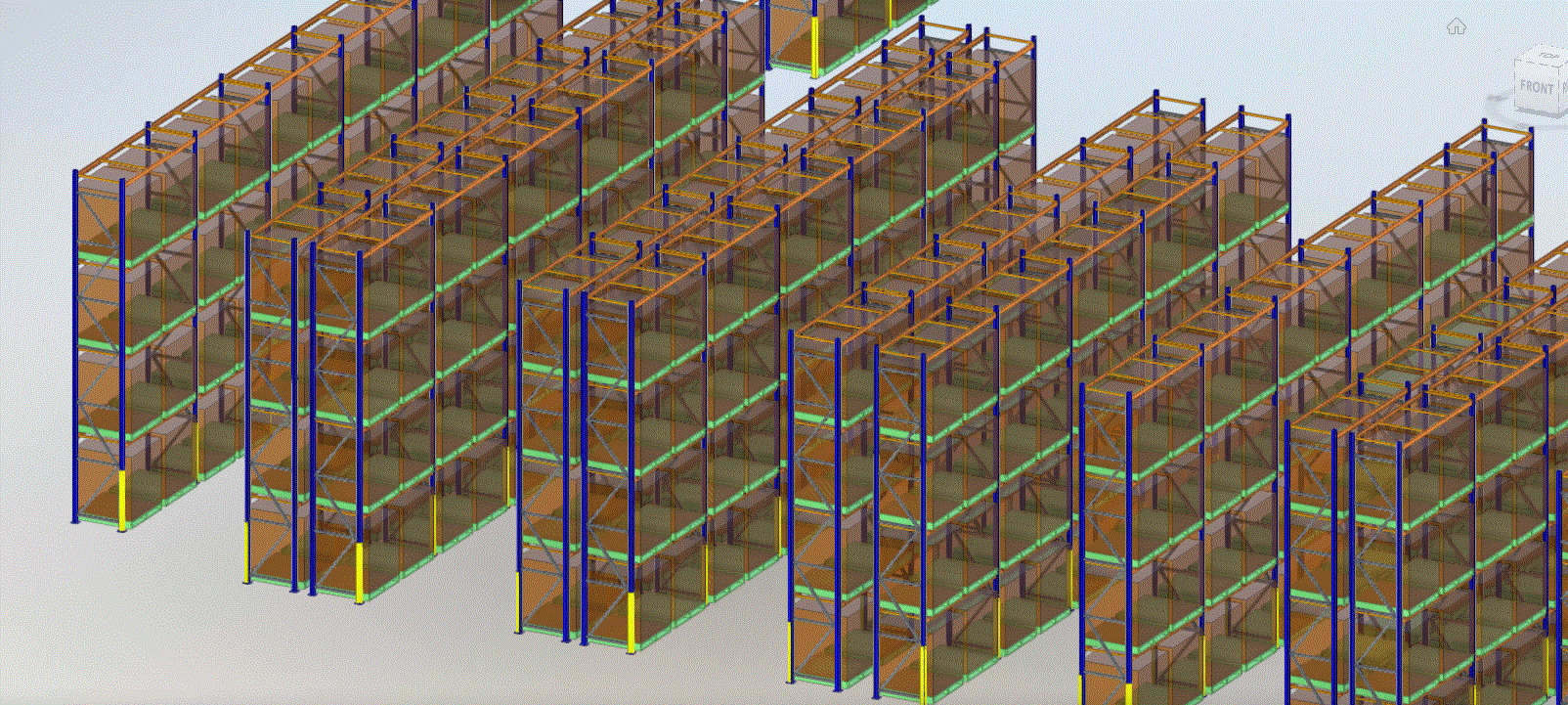

Our warehouse engineers and designers will develop detailed elevations of the proposed storage system to confirm accessibility and proper clearances for intended products. Detailed drawings of the facility will showcase rack configuration. Twinlode can also provide 3D drawings for integration with customer Building Information Modeling (BIM).

Preliminary Calculations

Twinlode Automation will provide preliminary calculations alongside the initial design. The engineering team then designs the pallet racking or material handling system according to applicable seismic code compliance.

As-Built (Installation) Drawings

If required, Twinlode can deliver a P.E. stamped calculation package and drawing set for customer record and submission to municipality for permitting.

As-Built (Installation) Drawings

To complete warehouse engineering services, Twinlode Automation will provide a final redlined field installation set of racking system drawings for recordkeeping purposes.

Contact Twinlode Automation for Warehouse Engineering & Design

Twinlode Automation has over 40 years of experience in integrating material handling and storage solutions. These solutions continue to support leading companies in food and beverage, agriculture, cold storage, and retail. Through full process involvement, Twinlode Automation delivers high value to every customer. Contact us for more information about our warehouse engineering services.